LEARNING OBJECTIVES

Upon completion of this module, the student will be able to:

1. Identify employer’s responsibilities for fall protection on construction sites

2. Review conventional fall protection systems

3. Discuss typical construction site hazards and fall protection systems required

4. Discuss fall protection training and what employers must provide

5. Understand workers’ rights in regards to safety from falls

Introduction

Historically, falls are the leading cause of fatalities in construction, accounting for about one-third of all fatalities in the industry. For example, the Bureau of Labor Statistics reported that there were 291 fatal falls to a lower level in construction in 2013, out of 828 total fatalities. OSHA recognizes that incidents involving falls are generally complex events, frequently involving a variety of factors. Consequently, the standard for fall protection deals with both the human and equipment-related issues in protecting workers from fall hazards. This publication is intended to help workers and employers better understand the Fall Protection in Construction standard’s requirements and the reasons behind them.

SUBPART M

Subpart M lays out the requirements and criteria for fall protection in construction workplaces. For example, it applies when workers are working at heights of 6 feet or more above a lower level. It also covers protection from falling objects, falls from tripping over or falling through holes, and protection when walking and working around dangerous equipment without regard to height. Subpart M provisions do not apply, however, to workers inspecting, investigating, or assessing workplace conditions prior to the actual start of work or after all construction work has been completed. The provisions of Subpart M can be found in Title 29 Code of Federal Regulations (CFR) Subpart M – Fall Protection, 29 CFR 1926.500, 29 CFR 1926.501, 29 CFR 1926.502, and 29 CFR 1926.503.

WHAT ARE EMPLOYERS’ RESPONSIBILITIES TO PROVIDE FALL PROTECTION?

Initially, employers must assess the workplace to determine if walking or working surfaces have the necessary strength and structural integrity to safely support the workers. Once it is determined that the work surfaces will safely support the work activity, the employer must determine whether fall protection is required (using the requirements set forth in 29 CFR 1926.501) and, if so, select and provide workers with fall protection systems that comply with the criteria found in 29 CFR 1926.502.

WHEN MUST EMPLOYERS PROVIDE FALL PROTECTION?

The 6-foot rule. Subpart M requires the use of fall protection when construction workers are working at heights of 6 feet or greater above a lower level. It applies at heights of less than 6 feet when working near dangerous equipment, for example, working over machinery with open drive belts, pulleys or gears or open vats of degreasing agents or acid.

WHAT CONSTRUCTION AREAS AND ACTIVITIES DOES SUBPART M COVER?

The standard identifies certain areas and activities where fall protection or falling object protection may be needed. For example, it might require fall protection for a worker who is: on a ramp, runway, or another walkway; at the edge of an excavation; in a hoist area; on a steep roof; on, at, above, or near wall openings; on a walking or working surface with holes (including skylights) or unprotected sides or edges; above dangerous equipment; above a lower level where leading edges are under construction; on the face of formwork and reinforcing steel; or otherwise on a walking or working surface 6 feet or more above a lower level. The standard may also require fall protection where a worker is: constructing a leading edge; performing overhand bricklaying and related work; or engaged in roofing work on low-slope roofs, precast concrete erection, or residential construction. In addition, the standard requires falling object protection when a worker is exposed to falling objects.

WHAT KINDS OF FALL PROTECTION SHOULD EMPLOYERS USE?

Generally, fall protection can be provided through the use of guardrail systems, safety net systems, or personal fall arrest systems. OSHA refers to these systems as conventional fall protection. Other systems and methods of fall protection may be used when performing certain activities. For example, when working on formwork, a positioning device system could be used. OSHA encourages employers to select systems that prevent falls of any kind, such as guardrails designed to keep workers from falling over the edge of a building.

EXAMPLES OF FALL PROTECTION REQUIREMENTS FOR CERTAIN CONSTRUCTION ACTIVITIES

Leading Edges – 29 CFR 1926.501(b)(2)

Each worker constructing a leading edge 6 feet or more above a lower level must be protected by guardrail systems, safety net systems, or personal fall arrest systems. 29 CFR 1926.501(b)(2)(i).

| Exception: When the employer can demonstrate that it is infeasible or creates a greater hazard to use these systems, the employer must develop and implement a fall protection plan which meets the requirements of 29 CFR 1926.502(k). See the section below on Fall Protection Plans. |

Workers must be protected by guardrail systems, safety net systems, or personal fall arrest systems, even if they are not engaged in leading edge work, if they are on a walking or working surface that is 6 feet or more above a level where leading edges are under construction. 29 CFR 1926.501(b)(2)(ii).

Overhand Bricklaying and Related Work – 29 CFR 1926.501(b)(9)

When workers perform overhand bricklaying and related work 6 feet or more above a lower level:

• They must be protected by guardrail systems, safety net systems, or personal fall arrest systems, or

• They must work in a controlled access zone (CAZ).

All workers reaching more than 10 inches below the level of the walking or working surface on which they are working must be protected by a guardrail system, safety net system, or personal fall arrest system.

Roofing Work on Low-Slope Roofs – 29 CFR 1926.501(b)(10)

A low-slope roof has a slope less than or equal to 4 in 12 (vertical to horizontal). When engaged in roofing work on a low-slope roof that has one or more unprotected side or edge 6 feet or more above lower levels, workers must be protected from falling by:

• Guardrail systems,

• Safety net systems,

• Personal fall arrest systems,

• A combination of conventional fall protection systems and warning line systems, or

• A warning line system and a safety monitoring system.

When engaged in roofing work on low-slope roofs 50 feet or less in width, the use of a safety monitoring system without a warning line system is permitted.

Working on Steep Roofs – 29 CFR 1926.501(b)(11)

A steep roof has a slope greater than 4 in 12 (vertical to horizontal). When working on a steep roof that has one or more unprotected side or edge 6 feet or more above lower levels, each worker must be protected by:

• Guardrail systems with toeboards,

• Safety net systems, or

• Personal fall arrest systems.

Residential Construction – 29 CFR 1926.501(b)(13)

Workers engaged in residential construction 6 feet or more above lower levels must be protected by conventional fall protection (i.e., guardrail systems, safety net systems, or personal fall arrest systems) unless another provision in 29 CFR 1926.501(b) provides for an alternative fall protection measure.

Exception: When the employer can demonstrate that it is infeasible or creates a greater hazard to use these systems, the employer must develop and implement a site-specific fall protection plan which meets the requirements of 29 CFR 1926.502(k). See the section on Fall Protection Plans, below. |

Note: For purposes of determining the applicability of section 1926.501(b)(13), the term “residential construction” is interpreted as covering construction work that satisfies the following two elements: (1) the end-use of the structure being built must be as a home, i.e., a dwelling; and (2) the structure being built must be constructed using traditional wood frame construction materials and methods. |

The limited use of structural steel in a predominantly wood-framed home, such as a steel I-beam to help support wood framing, does not disqualify a structure from being considered residential construction. For more information see OSHA’s Compliance Guidance for Residential Construction, STD 03-11-002.

Other Walking or Working Surfaces – 29 CFR 1926.501(b)(15)

As a general matter, each worker on a walking or working surface 6 feet or more above a lower level must be protected from falling by a guardrail system, a safety net system, or a personal fall arrest system.

| Exceptions: For exceptions to this rule that specify different requirements, see 29 CFR 1926.500(a)(2) and 29 CFR 1926.501(b)(1) through (b)(14). |

CONVENTIONAL FALL PROTECTION SYSTEMS

Guardrail Systems – 29 CFR 1926.502(b)

Guardrail systems are barriers erected to prevent workers from falling to lower levels. If the employer chooses to use guardrail systems to protect workers from falls, the following provisions apply:

• Top rails, or equivalent guardrail system members, must be 42 inches plus or minus 3 inches above the walking or working level. When workers are using stilts, the top edge of the top rail, or equivalent member, must be increased an amount equal to the height of the stilts. 29 CFR 1926.502(b)(1).

• Screens, midrails, mesh, intermediate vertical members, or equivalent intermediate structural members must be installed between the top edge of the guardrail system and the walking or working surface when there are no walls or parapet walls at least 21 inches high. 29 CFR 1926.502(b)(2).

• When midrails are used, they must be installed at a height midway between the top edge of the guardrail system and the walking or working level. 29 CFR 1926.502(b)(2)(i).

• When screens and mesh are used, they must extend from the top rail to the walking or working level and along the entire opening between top rail supports. 29 CFR 1926.502(b)(2)(ii). When necessary, screens and/or mesh must be installed in a manner to prevent a worker from falling underneath.

• When intermediate members (such as balusters) are used between posts, they must not be more than 19 inches apart. 29 CFR 1926.502(b)(2)(iii).

Other structural members (such as additional midrails and architectural panels) must be installed so that there are no openings in the guardrail system more than 19 inches wide. 29 CFR 1926.502(b)(2)(iv).

• Guardrail systems must be capable of withstanding a force of at least 200 pounds applied within 2 inches of the top edge, in any outward or downward direction, at any point along the top edge. 29 CFR 1926.502(b)(3).

• Midrails, screens, mesh, intermediate vertical members, solid panels, and equivalent structural members must be capable of withstanding a force of at least 150 pounds applied in any downward or outward direction at any point along the midrail or other member. 29 CFR 1926.502(b)(5).

• Guardrail systems must have a surface to protect workers from punctures or lacerations and to prevent clothing from snagging. 29 CFR 1926.502(b)(6).

• The ends of top rails and midrails must not overhang terminal posts, except where an overhang poses no projection hazard. 29 CFR 1926.502(b)(7).

• Steel and plastic banding cannot be used as top rails or midrails. 29 CFR 1926.502(b)(8).

• Top rails and midrails of guardrail systems must have a nominal diameter or thickness of at least 1/4 inch to prevent cuts and lacerations. 29 CFR 1926.502(b)(9).

• If wire rope is used for top rails, it must be flagged at not more than 6-foot intervals with high-visibility material. 29 CFR 1926.502(b)(9).

• When guardrail systems are used at hoisting areas, a chain, gate, or removable guardrail section must be placed across the access opening between guardrail sections during those times when hoisting operations are not taking place. 29 CFR 1926.502(b)(10).

• When guardrail systems are used at holes, they must be set up on all unprotected sides or edges. When a hole is used for the passage of materials, it must not have more than two sides with removable guardrail sections. When the hole is not in use, it must be covered or provided with a guardrail system along all unprotected sides or edges. 29 CFR 1926.502(b)(11) & (12).

• If guardrail systems are used around holes being used as access points (such as ladderways), gates must be used. Alternatively, the point of access must be offset to prevent workers from accidentally walking straight into the hole. 29 CFR 1926.502(b)(13).

• If guardrails are used on ramps and runways, they must be erected on each unprotected side or edge. 29 CFR 1926.502(b)(14).

• Manila, plastic, or synthetic rope used for top rails or midrails must be inspected as frequently as necessary to ensure its strength and stability. 29 CFR 1926.502(b)(15).

Safety Net Systems – 29 CFR 1926.502(c)

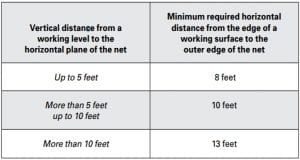

When safety nets are used, they must be installed as close as practicable under the walking or working surface on which workers are working and never more than 30 feet below that level. 29 CFR 1926.502(c)(1). When nets are used on bridges, the potential fall area from the walking or working surface to the net must be unobstructed. 29 CFR 1926.502(c)(1). All safety nets must be installed with sufficient clearance underneath to prevent a falling body from hitting the surface or structure below the net. 29 CFR 1926.502(c)(3). If the employer chooses to use nets, the following criteria apply:

Drop-testing is required to ensure that safety nets and safety net installations are working properly. See 29 CFR 1926.502(c) (4)(i) for more details. If an employer can demonstrate that it is unreasonable to perform a drop-test, then the employer or a designated competent person must certify that the net and its installation is in compliance with the standard. See 29 CFR 1926.502(c)(4)(ii) for more details on certification and certification records.

• Do not use defective nets. Inspect nets at least once a week for wear, damage, or deterioration of components such as net connection points. 29 CFR 1926.502(c)(5).

• Remove materials, tools, and other items as soon as possible from the net and at least before the next work shift. 29 CFR 1926.502(c)(6).

• To work properly, a safety net must have safe openings. Mesh openings must not exceed 36 square inches, and must not be longer than 6 inches on any side. Each opening, measured center-to-center of mesh ropes or webbing, must not exceed 6 inches. 29 CFR 1926.502(c)(7).

• All mesh crossings must be secured to prevent the openings from enlarging. 29 CFR 1926.502(c)(7).

• Use safety net (or section of net) with a border rope possessing a minimum breaking strength of 5,000 pounds. 29 CFR 1926.502(c)(8).

• Do not allow one weak link to compromise a safety net. Use connections between safety net panels that are as strong as integral net components and spaced no more than 6 inches apart. 29 CFR 1926.502(c)(9).

Personal Fall Arrest Systems – 29 CFR 1926.502(d)

A personal fall arrest system is a system used to safely stop (arrest) a worker who is falling from a working level. It consists of an anchorage, connectors, and a body harness. It also may include a lanyard, deceleration device, lifeline, or suitable combinations of these. Under Subpart M, body belts (safety belts) are prohibited for use as part of a personal fall arrest system.* When employers choose to use a personal fall arrest system as a means of worker fall protection they must:

• Limit the maximum arresting force on a worker to 1,800 pounds when used with a body harness. 29 CFR 1926.502(d)(16)(ii).

• Be rigged so that a worker can neither free fall more than 6 feet nor contact any lower level. 29 CFR 926.502(d)(16)(iii).

• Bring a worker to a complete stop and limit the maximum deceleration distance a worker travels to 3.5 feet. 29 CFR 1926.502(d)(16)(iv).

• Have sufficient strength to withstand twice the potential impact energy of a worker free falling a distance of 6 feet or the free fall distance permitted by the system, whichever is less. 29 CFR 1926.502(d)(16)(v).

• Be inspected prior to each use for wear, damage, and other deterioration. Defective components must be removed from service. 29 CFR 1926.502(d)(21).

| Note: Limited use of body belts (safety belts) can still be used as part of a positioning device system or fall restraint system See more information under Positioning Device Systems and Fall Restraint Systems, below. |

Personal Fall Arrest System Components

Snaphooks

• Snaphooks must be the locking type and designed and used to prevent disengagement from any component part of the personal fall arrest system. 29 CFR 1926.502(d)(5).

• Locking type snaphooks may also be used when designed for the following connections:

- directly to webbing, rope, or wire rope;

- to each other;

- to a Dee-ring to which another snaphook or other connector is attached;

- to a horizontal lifeline; or

- to any object which is incompatibly shaped or dimensioned in relation to the snaphook, such that unintentional disengagement could occur by the connected object being able to depress the snaphook keeper and release itself. 29 CFR 1926.502(d)(6).

Horizontal Lifelines

• On suspended scaffolds or similar work platforms with horizontal lifelines that may become vertical lifelines, the devices used to connect to a horizontal lifeline must be capable of locking in both directions on the lifeline. 29 CFR 1926.502(d)(7).

• Horizontal lifelines must be designed, installed, and used under the supervision of a qualified person, as part of a complete personal fall arrest system that maintains a safety factor of at least two. 29 CFR 1926.502(d)(8).

Vertical Lifelines and Lanyards

Vertical lifelines and lanyards must have a minimum breaking strength of 5,000 pounds. 29 CFR 1926.502(d)(9).

• Lifelines must be protected against being cut or abraded. 29 CFR 1926.502(d)(11).

Self-retracting Lifelines and Lanyards

• Self-retracting lifelines and lanyards that automatically limit free fall distance to 2 feet or less must be capable of sustaining a minimum tensile load of 3,000 pounds applied to the device with the lifeline or lanyard in the fully extended position. 29 CFR 1926.502(d)(12).

• Self-retracting lifelines and lanyards which do not limit free fall distance to 2 feet or less, ripstitch lanyards, and tearing and deforming lanyards must be capable of sustaining a minimum tensile load of 5,000 pounds applied to the device with the lifeline or lanyard in the fully extended position. 29 CFR 1926.502(d)(13).

Ropes and Straps

• Ropes and straps (webbing) used in lanyards, lifelines, and strength components of body belts and body harnesses must be made of synthetic fibers. 29 CFR 1926.502(d)(14).

Anchorages

• Anchorages used to attach personal fall arrest systems must be designed, installed, and used under the supervision of a qualified person, as part of a complete personal fall arrest system which maintains a safety factor of at least two. Alternatively, the anchorages must be independent of any anchorage being used to support or suspend platforms and must be capable of supporting at least 5,000 pounds per worker attached or be capable of supporting at least twice the expected impact load. 29 CFR 1926.502(d)(15).

TYPICAL CONSTRUCTION SITE HAZARDS THAT REQUIRE FALL PROTECTION

A construction environment poses many hazards requiring protection. Below are some fall hazards that cannot be overlooked.

Hoist Areas – 29 CFR 1926.501(b)(3)

Each worker in a hoist area must be protected from falling 6 feet or more by guardrail systems or personal fall arrest systems. There may be times when the guardrail systems (or chain, gate, or guardrail) must be removed in whole or part to facilitate hoisting operations. For example, during the landing of materials, a worker may need to lean through the access opening or out over the edge of the access opening to receive or guide equipment and materials. At such times a personal fall arrest system must be used to protect the worker from falling through the unprotected opening.

Holes – 29 CFR 1926.501(b)(4)

• Each worker on walking or working surfaces must be protected from falling through holes (including skylights) that are more than 6 feet above lower levels, by personal fall arrest systems, covers, or guardrail systems erected around such holes. 29 CFR 1926.501(b)(4)(i).

• Each worker on a walking or working surface must be protected from tripping in or stepping into or through holes (including skylights) by covers. 29 CFR 1926.501(b)(4)(ii).

Ramps, Runways, and Other Walkways – 29 CFR 1926.501(b)(6)

Each worker on a ramp, runway, or other walkway must be protected by guardrail systems against falling 6 feet or more.

Excavations – 29 CFR 1926.501(b)(7)

• Each worker at the edge of an excavation 6 feet or more deep must be protected from falling by guardrail systems, fences, or barricades when the excavation cannot be readily seen because of plant growth or other visual barrier. 29 CFR 1926.501(b)(7)(i).

• Each worker at the edge of a well, pit, shaft, and similar excavation 6 feet or more deep must be protected from falling by guardrail systems, fences, or barricades, or covers. 29 CFR 1926.502(b)(7)(ii).

Dangerous Equipment – 29 CFR 1926.501(b)(8)

• When working 6 feet or more above dangerous equipment, each worker must be protected by guardrail systems, safety net systems, or personal fall arrest systems. 29 CFR 1926.502(b)(8)(ii).

• When working less than 6 feet above dangerous equipment, each worker must be protected from falling into or onto the dangerous equipment by a guardrail system or equipment guards. 29 CFR 1926.502(b)(8)(i).

Wall Openings – 29 CFR 1926.501(b)(14)

Each worker working on, at, above, or near wall openings (including those with chutes attached), where the outside bottom edge of the wall opening is 6 feet or more above lower levels and the inside bottom edge of the wall opening is less than 39 inches above the walking or working surface, must be protected with a guardrail system, a safety net system, or a personal fall arrest system.

PROTECTION FROM FALLING OBJECTS

Falling objects can also pose a hazard to workers. Falling object protection must comply with the following provisions:

Guardrails – 29 CFR 1926.502(j)(5)

When guardrail systems are used to prevent materials from falling from one level to another, any openings must be small enough to prevent passage of falling objects.

Overhand Bricklaying and Related Work – 29 CFR 1926.502(j)(6)

During overhand bricklaying and related work, no materials or equipment except masonry and mortar may be stored within 4 feet of working edges. Excess mortar, broken or scattered masonry units, and all other materials and debris must be kept clear of the working area by removal at regular intervals.

Roofing Work – 29 CFR 1926.502(j)(7)

During roofing work, materials and equipment must not be stored within 6 feet of a roof edge unless guardrail systems are erected at the edge. Any materials piled, grouped, or stacked near a roof edge must be stable and self-supporting.

Toeboards – 29 CFR 1926.502(j)(1) through (4)

When toeboards are used as protection from falling objects, they must be erected along the edges of the overhead walking or working surface for a distance sufficient to protect workers working below. 29 CFR 1926.502(j)(1). Other criteria include:

• Toeboards must be capable of withstanding, without failure, a force of at least 50 pounds applied in any downward or outward direction at any point along the toeboard. 29 CFR 1926.502(j)(2).

• Toeboards must be at least 3.5 inches tall from their top edge to the level of the walking or working surface, must have no more than 0.25 inch clearance above the walking or working surface, and must be solid or have openings no larger than one inch in its greatest dimension. 29 CFR 1926.502(j)(3).

• Where tools, equipment, or materials are piled higher than the top edge of a toeboard, paneling or screening must be erected from the walking or working surface or toeboard to the top of a guardrail system’s top rail or midrail, for a distance sufficient to protect workers below. 29 CFR 1926.502(j)(4).

Canopies – 29 CFR 1926.502(j)(8)

When used as protection from falling objects, canopies must be strong enough to prevent collapse and to prevent penetration by any objects that may fall onto them.

FALL PROTECTION TRAINING

Requirements – 29 CFR 1926.503

Employers must provide a fall protection training program to workers who might be exposed to fall hazards. Training must include how to recognize fall hazards and how to minimize them. 29 CFR 1926.503(a)(1).

The employer must assure that each worker has been trained as necessary, by a competent person who is qualified in the following areas:

- The nature of fall hazards in the work area. 29 CFR 1926.503(a)(2)(i).

- The correct procedures for erecting, maintaining, disassembling, and inspecting the fall protection systems to be used. 29 CFR 1926.503(a)(2)(ii).

- The use and operation of controlled access zones; guardrail, personal fall arrest, safety net, warning line, and safety monitoring systems; and other protection to be used. 29 CFR 1926.503(a)(2)(iii).

- The role of each worker in the safety monitoring system when the system is used. 29 CFR 1926.503(a)(2)(iv).

- The limitations on the use of mechanical equipment during the performance of roofing work on low-slope roofs. 29 CFR 1926.503(a)(2)(v).

- The correct procedures for equipment and materials handling and storage and the erection of overhead protection. 29 CFR 1926.503(a)(2)(vi).

- The role of workers in fall protection plans. 29 CFR 1926.503(a)(2)(vii).

- OSHA’s fall protection requirements, published as Subpart M. 29 CFR 1926.503(a)(2)(viii).

Verification of Training

Employers must verify worker training by preparing a written certification record. The record must contain the name or other identity of the worker trained, the dates of the training, and the signature of either the person who conducted the training or the employer. 29 CFR 1926.503(b)(1).

When an employer has reason to believe that an affected worker does not recognize existing fall hazards at some point after the initial training, the employer is required to provide retraining for that worker. For example, workers must be retrained when:

- Changes in the workplace render previous training obsolete. 29 CFR 1926.503(c)(1).

- Fall protection equipment or systems have changed. 29 CFR 1926.503(c)(2).

- Inadequacies in workers’ knowledge or use of fall protection systems or equipment indicate that they have not adequately understood or retained previous training. 29 CFR 1926.503(c)(3).

WORKERS’ RIGHTS

Workers have the right to:

• Working conditions that do not pose a risk of serious harm.

• Receive information and training (in a language and vocabulary the worker understands) about workplace hazards, methods to prevent them, and the OSHA standards that apply to their workplace.

• Review records of work-related injuries and illnesses.

• File a complaint asking OSHA to inspect their workplace if they believe there is a serious hazard or that their employer is not following OSHA’s rules. OSHA will keep all identities confidential.

• Exercise their rights under the law without retaliation, including reporting an injury or raising health and safety concerns with their employer or OSHA. If a worker has been retaliated against for using their rights, they must file a complaint with OSHA as soon as possible, but no later than 30 days.

REFERENCES

Fall Protection in Construction: